<TRANSCRIPT>

Hey there Everybody, Bob Craft here, for Advanced Technology Solutions, where our motto is SOLUTIONS BEFORE PROBLEMS.

Earlier this week I had some corrective maintenance done on my wrist. Which is why I’m not wearing my signature hand-tied bow tie this time – because that requires two fully functioning opposable thumbs!

It got me thinking again about physical human analogies to industrial machinery condition monitoring and maintenance.

Let me remind you, I am not a medical professional.

None of what I say or show here today should be taken as actual medical advice.

Several of us in the extended ATS family have recently had corrective maintenance performed on ourselves. It would be terribly inappropriate for me to discuss any of their cases so I will restrict details and analogies just to myself. Suffice it to say, though, that all of our respective surgical decisions were made based on following the exact same principles of structured measurements, observations, and the appropriate use of technology just like we do when collecting data on your industrial machinery and systems to support corrective action recommendations.

When I first discussed the increasing pain I was having with my doctor, he shot some X-rays and we reviewed them together. His diagnosis was surgery at some undefined point in the future because the situation with the bones in my wrist was not self-reversing, and was expected to degrade more and more rapidly over time.

But he also offered me the opportunity for a shot that would be expected to eliminate the pain for a while and we could continue to monitor the situation. Of course, I opted for the quick pain elimination shot because it was right in the middle of eco-tour boating season – which everybody who knows me knows how much I enjoy driving those trips!

Check out these pictures of me and of some of my closest friends on the river.

You can clearly see why I wanted to put off surgery until after the boating season ended!

The real point of this is that knowledge of the condition of your machinery is power. Once you understand that a challenging situation exists, you should be able to take control of it and do the proper planning and scheduling needed to minimize the consequences of the inevitable functional failure.

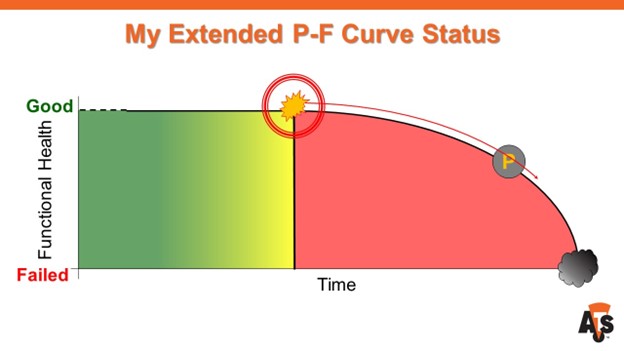

In the car on the way home from the doctor’s office, the condition-monitoring part of my brain kicked in. And you guessed it, the extended P-F curve started growing in my head.

I had already gone through the transition from my wrist was fine through the part where irreversible damage had started and it was on the accelerating downward slope towards functional failure. And you know what that whole thing reminded me of? Trying to fix a bad bearing that is making hellacious noises by quieting it down with grease!

We’ve all done it. Sounds bad, pump grease in it until it sounds OK. And we walk away happy that we solved the problem because it’s not making any more noise, at least not for now.

But did we solve the right problem? The damage in the bearing is still there, we just masked the symptoms and perhaps deferred the functional failure for a few more days, if that. In one specific case that I’m familiar with, the plant got really lucky with the greasing decision – I’ve seen plenty of cases where it didn’t go so well. These folks WERE able to continue production through the week and did the bearing change during already scheduled downtime over the weekend.

They got lucky.

Looking at the damage on the internal surfaces, it probably wouldn’t have lasted more than another day or 2, additional greasing or not! Sorry, they wouldn’t allow us to share pictures – the plant was pretty embarrassed that they had let the problem go for as long as they had without replacing it sooner! This wasn’t a bearing they monitored routinely, but you’d better believe it is now because it had actually happened before, which of course, they didn’t tell us until after the fact.

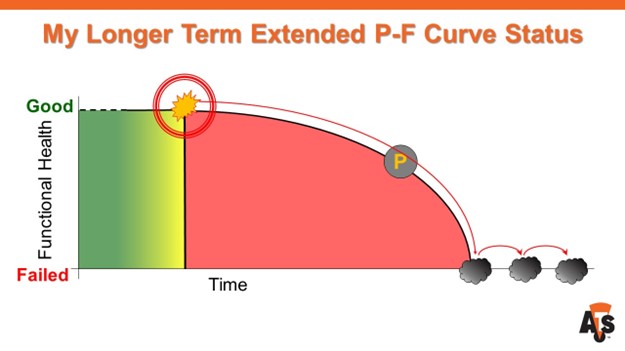

In my case, I finished the eco-tour season relatively pain-free.

About a month after we put the boat to bed for the winter, I experienced my first of several functional failures, unexpectedly dropping things I thought I had a good grip on and the pain was back with a vengeance.

My goal instantly became getting it fixed before we started running the eco-trips again in the spring!

So today’s non-medical advice for taking proper care of your production machinery message is this:

- Collect and evaluate appropriate data.

- Understand what it means, and

- Take the right corrective actions in a timely manner to prevent the functional failure from happening when the machine is in service.

This is what we mean when we say Solutions Before Problems!

So reach out to us at ATS for help monitoring and diagnosing issues on your machinery.

Our skilled team can set up and run a program that will help significantly improve your productivity while lowering your operating costs.

Think of it like this – you should treat both your production machinery and your body systems with the same amount of respect. One directly impacts your livelihood and your ability to live in the manner to which you’ve become accustomed, while the other can significantly impact your life itself and the quality thereof.

Stay safe out there, and please, make sure that when you go home at the end of your shift, you get there with all of your body parts intact.

And I hope to see you on the water in the spring.

0 Comments