Our services

CUSTOMIZED PROGRAMS

THE BEST IN THE FIELD

COMBINATION OF TECHNOLOGIES

ONLINE REPORTING

Our mission is to provide a high level of professional, consistent and accurate reliability solutions in partnership with our clients.

Your success is our success!

ATS at the SMRP Conference October 17-21

ATS will be attending the annual SMRP Conference in Jacksonville, Florida. The conference runs from Monday, October 17 through Friday, October 21. ATS is committed to the Society for Maintenance and Reliability Professionals. We support the organization’s efforts to...

Start Small and Build Support

Picture this: you are a maintenance manager who is in the planning stages for a new predictive maintenance (PdM) program. Other initiatives like this have failed in the past, but you are determined to change the maintenance culture in your facility. To enable this,...

Oil Analysis for Predictive Maintenance

Predictive maintenance (PdM) is a broad field of many overlapping technologies, all of which have one common goal: find faults in a machine’s condition before the machine fails. On their own, predictive technologies each have their own strengths. For example, the...

Key Traits of Successful PdM Programs

In our last post, I touched on some negative factors which can lead to program failure. Today, let’s flip the script and take a look at three positive traits of successful predictive maintenance (PdM) programs: top-down support, communication and documentation, and...

Three Reasons PdM Programs Fail

It is easy to justify starting a predictive maintenance (PdM) program. A successful PdM program will monitor all of a facility’s critical assets, detect failures before they occur, and perform necessary maintenance on those assets, reducing repair costs and downtime....

The Reliability Conference

The Reliability Conference is being held from April 11-15 in Las Vegas, Nevada. Per the conference website: One of the largest gatherings of industry professionals, The RELIABILITY Conference is where the most respected and distinguished subject-matter experts,...

2016 Intro to Predictive Maintenance & Vibration Analysis Training – April 18-19

INSTRUCTOR - RYAN BUI - is an Iowa and Iowa State graduate in engineering. His expertise areas are in preventive, predictive and proactive maintenance concepts, technologies and implementation. He has completed level three in vibration analysis and has been an...

Vibration Analysis Using Overall Vibration Alarms

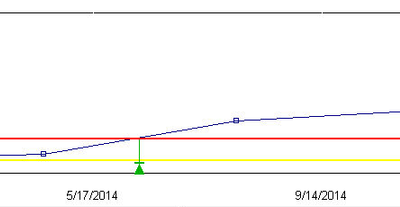

As an organization’s predictive maintenance (PdM) program grows, limitations on manpower require the technicians and/or analysts to work more efficiently to monitor the growing list of critical equipment. Often, practitioners will look to cut corners on vibration...

Steam Trap Surveys Identify Problems and Save Money

Steam traps play a significant role in steam systems in manufacturing plants. When operating effectively, steam traps retain heat within the system by removing condensate, air, and other gases from the system. As cold winter weather begins to set in, your steam system...