Ballbar data will quantify faults in the machine center such as servo mismatch, stick-slip error, straightness of the axes, lateral play, backlash, reversal spikes, circularity error, scale, and machine geometry. Each of these conditions can be trended over time.

Condition Monitoring and Maintenance Management – Part 1 – Identification

We live in an age where information has become more important than just data. Management rarely wants to know more than what needs to be done and when to machinery assets, to ensure safety and ongoing production. The most effective way to communicate recommended...

Online Monitoring – The Complete Healthcare Package for your Business

Imagine if you went to your doctor for your annual physical and instead of examining you, he (or she) says, “Rather than examining you today, I’d like to attach tiny sensors to your body that will trip an alarm in our office if anything seems out of the ordinary. Then...

Predictive Maintenance for Our Most Valuable Asset

We believe our people are our most important asset. That is why we bring in a team of health professionals to perform “wellness checks” for each of our employees. It’s a predictive maintenance program for our people! These wellness checks involve online questionnaires...

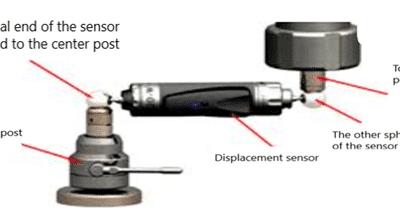

Ballbar Analysis for CNC Machines – Part 2

Searching the internet, there are countless PdM articles about applying predictive technologies to hundreds of different types of production machines, but there are very few and specific documents about predictive maintenance with regard to CNC assets due to various...

The Case for Installing Specialized IR Windows

Photo Credit: IRISS Infrared inspection windows are usually found on high voltage equipment where opening panels for inspection is not always safe and feasible. During a shutdown, panels are cut to accommodate IR inspection windows in locations that give the best view...

Online System, How Does it Really Work? – Part 2

Part 2 - The surge of modern online system availability For the sake of clarity in this article, the previously mentioned surveillance system will now be called an online system, a common reference at this time in the industry. For most of us in the PdM arena, the...