Vibration, in the context of condition monitoring and evaluation, is typically thought of as an indicator of damage in a machine. We look for things like imbalance, misalignment, and bearing and gear defects, to name just a few examples, by focusing on specific frequencies in the vibration spectrum to “see” what bad things may be going on inside the guts of the machine. Unfortunately, we rarely consider what vibration may be ding TO a machine until we see one or more distress-indicating frequencies pop their heads up out of the background noise in the signal, letting us know that physical damage has started. Some machines are expected to vibrate excessively, like diesel engines or reciprocating compressors. But these are structurally designed to be beefy enough to handle the violence that occurs within them. Most other machines, however, are designed to run smoother and thus don’t have the structure needed to withstand high vibration levels. Look at most motor or pump operation and maintenance manuals and you will find a maximum vibration level for the machine. That level doesn’t mean that you should run it at that amplitude, in fact, it probably means that if you run it at or over that amplitude, the OEM probably isn’t going to honor the warranty when it fails!

The most commonly overlooked source of damaging vibration in machinery is resonance. We see it, we know it’s there, but so long as it is not excessive we flag it and ignore it. Sometimes, though, we don’t even realize it is there, especially when major forcing frequencies are not coincident with a resonant frequency. Knowing resonant frequencies is critical in turbomachinery because of how long they typically take to come up to speed and coast down when they come offline, both of which take a significant number of minutes. Operators do their best to drive up speed quickly through resonances to avoid the high vibration, and probably damage, that results from lingering at and close to resonant frequencies. Thus the term “critical speed.”

All machines have critical speeds, but in most cases, they start up to and stop from full speed in just a couple of seconds so there is essentially no time lingering around a critical speed. This WAS the case for a critical cooling pump at one of ATS’ Customers, a leading biotechnology company. As originally built, the machine was powered by a 6-pole motor and ran at just under 1200 RPM (60 Hz synchronous speed minus a little slip). This machine had been running steadily for years, with overall vibration varying between about 0.1 and 0.2 inches per second, depending on load.

The Customer, unbeknownst to ATS, decided to improve the cooling system’s efficiency and made some changes. ATS collected data on the machine and discovered that the overall vibration had increased by OVER a factor of 4 from the previous measurement!

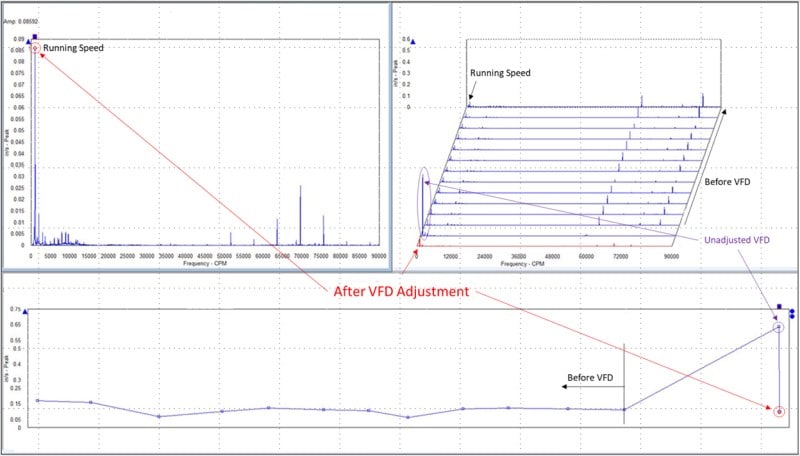

A review of the work history since ATS’ previous visit revealed that a VFD had recently been installed. Instead of being driven by 60 Hz power, the motor was now typically being driven by about 42Hz power, which put the running speed right on the natural, resonant frequency of the pump mounted on its foundation! This was confirmed by a series of run-up and coast-down tests. The vibration was very directional with the highest rotational speed amplitude 8 times higher in the vertical direction than the horizontal and axial directions. The highest vertical amplitude was 0.637 inches per second with the VFD set to 42.5 Hz.

The best course of action was to avoid operating the pump in the electrical frequency range of 40Hz – 45Hz. The site lead electrical engineer set the skip band in the VFD to avoid operating in this range. It will pass through this range very quickly when necessary, but never linger within it. Since this was done, vibration has been steady at 0.1 inches per second.

The moral of this story – changes to improve operating reliability and efficiency are great, and we at ATS always encourage our Customers to do so. Switching fixed-speed machines to variable speed requires a little more thought than just determining if the motor/driven component can handle the change. We recommend and are fully prepared to support you with structural resonance testing to help determine if the installed machine would be able to handle the speed changes without beating itself to death or if it might be appropriate to plan for a speed avoidance band in the VFD controller logic or if a structural change might be best.

0 Comments