Ballbar data will quantify faults in the machine center such as servo mismatch, stick-slip error, straightness of the axes, lateral play, backlash, reversal spikes, circularity error, scale, and machine geometry. Each of these conditions can be trended over time.

Baselines for Vibration Analysis

Every band relies on its bassline—that low, thumping sound that helps establish the rhythm, tempo and signature sound of a song. Your predictive maintenance (PdM) program should rely on a baseline, too—especially in the area of vibration analysis. Without a baseline,...

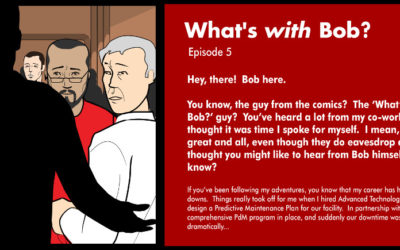

What’s With Bob? – Episode 5

Hey, there! Bob here. You know, the guy from the comics? The 'What's with Bob?' guy? You've heard a lot from my co-workers, and I thought it was time I spoke for myself. I mean, they're great and all, even though they do eavesdrop a lot. But I thought you might like...

What’s With Bob? – Episode 4

Bob got his bounce back. Sounds like Bob made a compelling case to management. Advanced Technology Solutions, Inc. is back on the job helping him get the most from his company's Predictive Maintenance Program. The newfangled system management put in place was only...

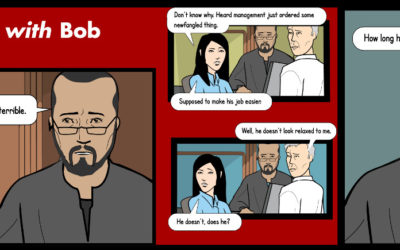

What’s With Bob? – Episode 3

Why is Bob pulling his hair out? "Newfangled" isn't necessarily better. What Bob's coworkers don't know is that management's move to an online Predictive Maintenance Program means the collected data is overwhelming--and possibly unreliable. Bob needs to call his...

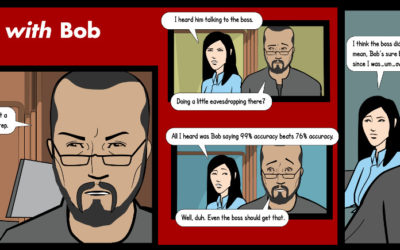

What’s With Bob? – Episode 2

What's going on is Advanced Technology Solutions, Inc., the premiere provider of Reliability Driven Predictive Maintenance Programs. Unbeknownst to Frank, ATS has been monitoring his plant's equipment for months. ATS's state-of-the-art predictive maintenance service...

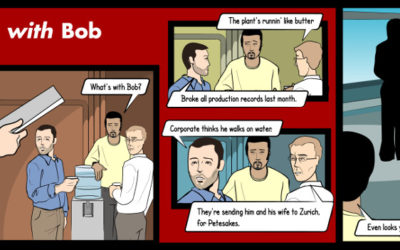

What’s With Bob? – Episode 1

Want to know Bob's Secret? What the guys don't know is that Bob has hired Advanced Technology Solutions, Inc., the premiere provider of Reliability Driven Predictive Maintenance Programs. ATS monitors the equipment at Bob's plant, predicting maintenance and repair...